3 Piece Ball Valve Manufacturer in Mumbai

Price 2000 INR/ Unit

3 Piece Ball Valve Manufacturer in Mumbai Specification

- Pressure

- 150# to 800# (10 Bar to 63 Bar)

- Caliber

- Full Bore / Reduced Bore

- Structure

- 3 Piece Body

- Channels

- 2 Way / 3 Way

- Connection

- Screwed / Flanged / Socket Weld / Butt Weld

- Material

- Stainless Steel / Cast Steel / Forged Steel / Brass / PVC

- Power

- Manual / Pneumatic / Electric Operated

- Media

- Water, Oil, Gas, Air, Steam, Chemicals

- Temperature of Media

- -20C to 200C

- Port Size

- 1/2 to 12 (DN15 - DN300)

- Flange

- ANSI / DIN / JIS Standard Flanges

- Finish

- Chrome Plated / Powder Coated / Natural Finish

- Application

- Industrial, Water Treatment, Petrochemical, Oil & Gas, Chemical Processing

- Body Material Grade

- CF8, CF8M, WCB

- Design Standard

- BS 5351/ASME B16.34

- Leakage Class

- Class VI

- Body Wall Thickness

- ASME B16.34

- Testing Standard

- API 598/BS EN 12266

- ISO Mounting Pad

- Available

- Ball Material

- SS 304/316

- Seat Material

- PTFE/TFM/RPTFE

- End Connection

- BSP/NPT/Flanged

- Blowout Proof Stem

- Yes

- Fire Safe Design

- Available

- Operation

- Lever Operated

- Antistatic Device

- Yes

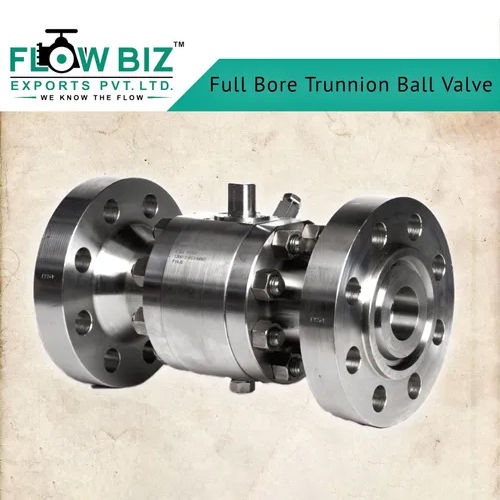

About 3 Piece Ball Valve Manufacturer in Mumbai

FlowBiz brand 3-piece floating ball valves consist of three pieces, two end connections & a body. The end connections are typically Flanged, threaded, or welded to the pipe. Users can easily remove the main body for cleaning or repair without removing the end connection. Hence, it is vital to prevent a line shutdown if maintenance is required. Our engineers have incarnated perfection in the valve design to make it an easy & smooth functioning valve. FlowBiz 3-piece Floating Ball Valves are easy to disassemble for maintenance and easy swapping of internal parts.

3-Piece Design Ball Valve's seats and seals must be routinely replaced; three pieces allow for easy disassembly, servicing, and reassembly without significantly cutting the pipe. If users need to weld the valve, moving the body with trims out of the way while welding is possible, ensuring the internals stay intact. FlowBiz three-piece ball valves allow change elastomers to adjust different process conditions, temperatures, pressures, and flows. 3-piece ball valve suits industries like petrochemicals, pharmaceuticals, chemicals, food processing, and HVAC.

FlowBiz is the best manufacturer of 3-piece ball valves in India. We supply 3-piece ball valves in Ahmedabad, Vapi, Valsad, Surat, Gandhidham, Kutch, Ankleshwer, Bharuch, Mumbai, Nashik, Pune, Thane, Aurangabad, Satara, Sangli, Nagpur, Kolhapur, Indore, Dewas, Bhopal, Chennai, Coimbatore, Selam and all over India.

Advanced Engineering and Flawless Operation

Our 3 Piece Ball Valves feature a durable 3-piece body design, offering easy maintenance and high reliability for demanding industrial environments. With seat options like PTFE, TFM, and RPTFE and ball materials in SS 304/316, these valves provide excellent chemical resistance and long lifespan. Choose from full or reduced bore, and multiple port sizes to suit your operational needs.

Multiple End Connections and Mounting Applications

Tailored for diverse piping systems, our valves are available with BSP/NPT threading or flanged, socket weld, and butt weld end connections. Theyre also compatible with ISO mounting pads, allowing for simplified automation and integration into existing setups. Flange standards include ANSI, DIN, and JIS, accommodating a wide variety of global applications.

Strict Quality Standards and Safety Features

Every valve undergoes rigorous testing per API 598 and BS EN 12266, ensuring Class VI leakage performance. Fire safe design and blowout proof stem deliver peace of mind, while antistatic devices provide added safety in flammable environments. Our valves follow BS 5351/ASME B16.34 design standards and offer wall thickness as per ASME B16.34 guidelines for optimal durability.

FAQs of 3 Piece Ball Valve Manufacturer in Mumbai:

Q: How are your 3 piece ball valves used in industrial applications?

A: Our ball valves are designed for precise flow control and shut-off in industrial, water treatment, petrochemical, oil & gas, and chemical processing sectors. Suitable for handling water, oil, gas, steam, air, and chemicals, they deliver reliable performance even under demanding conditions and high pressures ranging from 150# to 800# (10-63 Bar).Q: What seat materials are available, and how do I choose between PTFE, TFM, and RPTFE?

A: We offer PTFE, TFM, and RPTFE seat optionseach providing excellent chemical resistance. PTFE is most used for general applications; TFM offers improved mechanical properties at higher temperatures, while RPTFE combines PTFEs chemical resistance with enhanced wear resistance, making it ideal for abrasive or cycle-intensive settings.Q: When is a fire safe design recommended for ball valve installations?

A: Fire safe design is crucial wherever theres a risk of fire exposure from flammable media, such as in chemical processing or oil & gas installations. Our fire safe valves are engineered to maintain tight shut-off and limit leakage during and after exposure to fire, complying with industry safety standards.Q: Where can your 3 piece ball valves be installed?

A: The valves can be installed in a wide range of settings, including pipelines for industrial processes, water plants, oil refineries, and chemical factories. Their compatibility with various end connectionslike BSP, NPT, flanged, socket weld, and butt weldmakes them suitable for new projects or system upgrades worldwide.Q: What is the process for testing the ball valves before delivery?

A: Each valve undergoes strict quality testing according to API 598 and BS EN 12266 standards. This includes leakage class testing (Class VI) and pressure assessments to ensure maximum safety and performance before dispatching to customers.Q: How does the blowout proof stem and antistatic device benefit the operator?

A: The blowout proof stem ensures the stem cannot be ejected from the valve under pressure, significantly increasing operator safety. The antistatic device prevents the accumulation of static electricity, a critical feature when handling flammable or hazardous media, reducing the risk of fire or explosion.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valve Category

Ball Valve Manufacturer in Rajkot

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other, Stainless Steel, Brass, Cast Iron, Mild Steel

Application : Industrial, Domestic, Water Line, Oil & Gas, Chemical

Media : Other, Water, Gas, Oil, Air, Steam

Structure : Ball

Single Piece Ball Valve Manufacturer in Gandhidham

Price 2000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other, Stainless Steel / Carbon Steel / Brass

Application : Industrial / Commercial / Water Treatment / Chemical Processing

Media : Other, Water, Oil, Gas, Air, Chemical

Structure : Other, Single Piece

Double Eccentric Design Offset Disc Double Flange Butterfly Valve

Price 6000 INR / Unit

Minimum Order Quantity : 1 Number

Material : Other, Carbon Steel / Cast Iron / Stainless Steel

Application : Water Supply, Wastewater, Industrial Pipelines

Media : Other, Water, Oil, Gas, Steam

Structure : Other, Double Flange, Double Eccentric Design

Stainless Steel Full Bore Ball Valve

Price 2500 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Application : Industrial

Media : Gas

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free