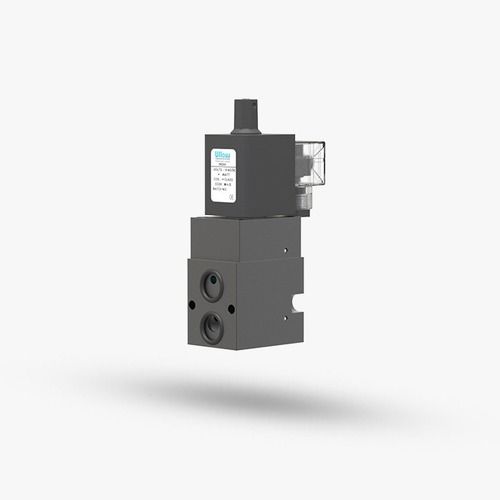

3/2 X 5/2 Convertible Single Solenoid Directional Control Namur Poppet Valve (Monostable)

Price 2500 INR/ Number

3/2 X 5/2 Convertible Single Solenoid Directional Control Namur Poppet Valve (Monostable) Specification

- Material

- Aluminum body with chemical-resistant seals

- Valve Type

- Monostable (single solenoid, spring return)

- Control System

- Solenoid-operated, spring return

- Connection Type

- Namur interface

- Valve Size

- Standard Namur mounting

- Features

- Quick conversion between 3/2 and 5/2 function, compact design, maintenance-free operation, high cycling life

- Sealing

- Nitrile (NBR)

- Application

- Industrial pneumatic systems, process automation, actuator control

- Usage

- Industrial

- Structure

- Poppet type, Namur interface

- Voltage

- 24V DC (other voltages available on request)

- Type

- 3/2 or 5/2 convertible, single solenoid

- Power

- Pneumatic with electrical solenoid actuator

- Pressure

- 2 to 8 bar (29 to 116 psi)

- Media

- Filtered and lubricated air

- Port Size

- 1/4 BSP (Namur standard interface)

- Color

- Black

- Temperature

- -10C to +60C

- Disc

- Poppet valve

- Pin

- DIN 43650 Form A

- Protection Class

- IP65 (with proper electrical connection)

- Fluid Temperature

- -10°C to +60°C

- Mounting

- Direct Namur interface, surface mount

- Manual Override

- Yes, standard

- Operating Position

- Any position

- Response Time

- <20 ms

- Weight

- Approximately 0.5 kg

- Coil Consumption

- ~3W max

- Ambient Temperature

- -10°C to +50°C

3/2 X 5/2 Convertible Single Solenoid Directional Control Namur Poppet Valve (Monostable) Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7 Days

About 3/2 X 5/2 Convertible Single Solenoid Directional Control Namur Poppet Valve (Monostable)

Valve Specifications

Type : 3/2 - 5/2

Design : Internal Pilot Operated Poppet Valve

Port Size : In / Out / Exhaust - 1/4 BSP

Media : Compressed Air (Filtered & Lubricated)

working Pressure Range : 2-10 Bar

Orifice : 7mm

Ambient / Media Temperature : 5C - 60C

Materials of Construction : Aluminium, Nitrile, Brass, Polymer

Coil Specification

Coil Features : High Reliability Unaffected by Voltage Surges. Easy coil changes coil lockable in 4X90 position or freely movable in between as require.

Coil Housing : Epoxy square coil, Metallic round enclosure, IP-67 Flameproof enclosure, IP-68 Weatherproof enclosure.

Versatile Design and Quick Conversion

Effortlessly switch between 3/2 and 5/2 functions to match your system requirements using the convertible poppet mechanism. This design flexibility makes the valve ideal for diverse industrial applications, offering a quick solution without the need for additional hardware.

Durable Performance for Industrial Automation

Constructed from a robust aluminum body with chemical-resistant nitrile seals, the valve ensures lasting durability and high cycling life. It reliably operates under a wide temperature range and pressure, making it perfect for demanding environments in process automation and actuator control industries.

Simple Installation and Maintenance-free Operation

With a direct Namur interface and surface mounting capability, installation is both simple and secure. The maintenance-free design minimizes downtime, supported by the reliable spring return and manual override for operational flexibility during maintenance or emergencies.

FAQ's of 3/2 X 5/2 Convertible Single Solenoid Directional Control Namur Poppet Valve (Monostable):

Q: How is the function converted between 3/2 and 5/2 in this valve?

A: The valve features a convertible mechanism that allows users to quickly switch between 3/2 and 5/2 operation modes, adapting to your pneumatic system's requirements without extensive reconfiguration or replacement parts.Q: What are the benefits of using a Namur poppet valve in industrial automation applications?

A: Namur poppet valves provide direct, reliable mounting to actuators, fast response times, and robust operation under varying conditions. Their compact design supports high cycling rates and ensures compatibility with standardized interfaces in process automation.Q: When should I utilize the manual override feature?

A: The manual override can be engaged during setup, maintenance, or in emergency situations where electrical control is unavailable. This feature enables safe manual actuation and testing without energizing the solenoid coil.Q: Where can this valve be mounted in an industrial setup?

A: It is designed for direct Namur interface mounting, commonly found on pneumatic actuators and control manifolds in processing plants, manufacturing lines, and automated actuator systems.Q: What media and pressure ranges are suitable for this valve?

A: This valve is intended for filtered and lubricated air, operating efficiently within a pressure range of 2 to 8 bar (29 to 116 psi), ensuring optimal performance and seal longevity.Q: How does the IP65 protection class benefit industrial applications?

A: With an IP65 protection rating (when properly connected electrically), the valve is shielded against dust and water jets. This ensures dependable operation even in harsh industrial environments.Q: What are the power and voltage requirements for this valve?

A: The valve requires a 24V DC supply for the solenoid, drawing approximately 3W. Other voltage options can be provided on request to fit specific installation standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Solenoid Valve Category

3/2 Single Solenoid Namur Poppet Valve (Normally Close)

Price 1000 INR / Number

Minimum Order Quantity : 1 Unit

Material : Aluminium Body with Brass/Engineering Polymer Components

Valve Type : Namur Poppet Valve

Control System : Electrical solenoid actuation

Port Size : 1/4 BSP (Namur Interface Porting)

3 2 5 2 Single Solenoid Namur Valve With Spring Return

Price 15000 INR / Number

Minimum Order Quantity : 1 Unit

Material : Aluminium body

Valve Type : 3/2 or 5/2 Namur valve

Control System : Solenoid electricopneumatic

Port Size : NAMUR standard

Gas Solenoid Valve

Price 11000 INR / Number

Minimum Order Quantity : 1 Unit

Material : Brass body Stainless steel actuator

Valve Type : Solenoid

Control System : Solenoid

Port Size : 1/2 inch

3/2 Hand Lever Valve

Price 7000 INR / Number

Minimum Order Quantity : 1 Unit

Material : Aluminum alloy body Plastic lever

Valve Type : Directional control valve

Control System : Manual

Port Size : 1/4 inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS